-contain-250x120.jpg)

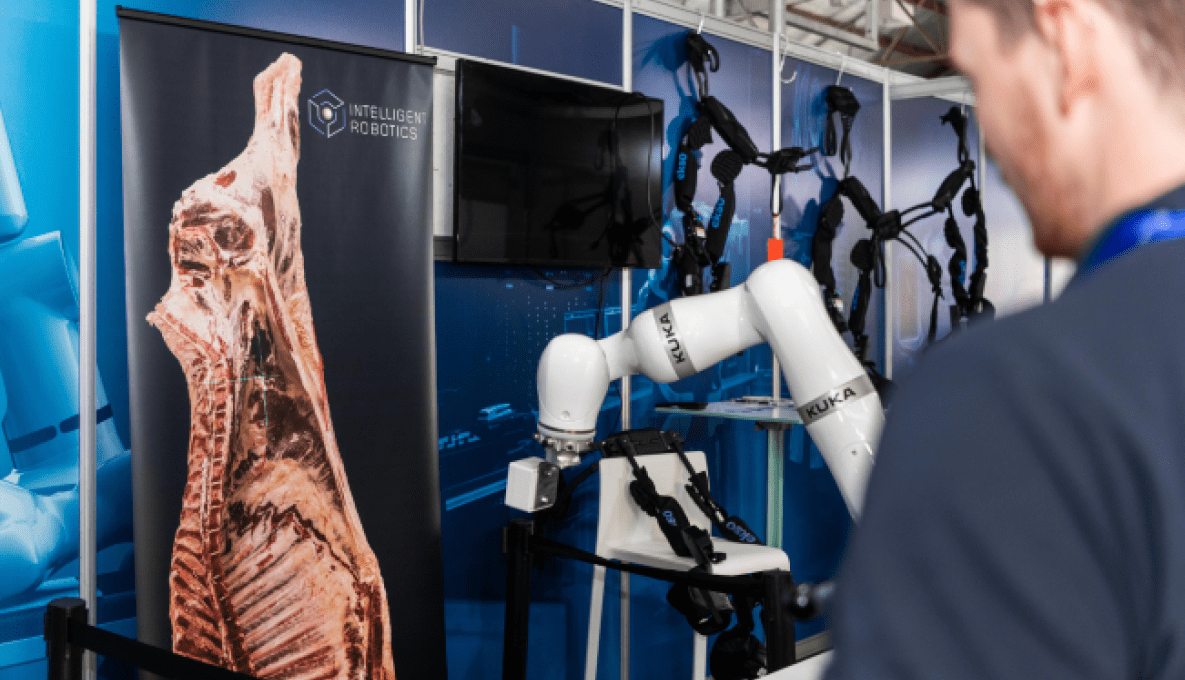

AMPC sets new industry challenge for innovation in red meat abattoirs

The Australian Meat Processor Corporation (AMPC) might be the Research and Development Corporation for the red meat processing industry, but it’s drawing inspiration from a very different R&D agency to help find the answers to some mammoth questions. AMPC is now seeking problem solvers and investors with innovative solutions to make waterless knife sterilisation for meat processing plants a reality.

The Defence Advanced Research Projects Agency (DARPA) is the research and development arm of the United States Department of Defence – responsible for the development of emerging technologies for use by the military.

“We are following in the footsteps of DARPA’s innovation approach and over the past eight months AMPC has followed a method established by them – setting global innovation challenges for global providers to deploy their innovative minds to industry problems,” said AMPC’s Senior Manager On Plant Innovation, Sean Starling.

AMPC is specifically targeting innovators from outside the meat industry provider group and in less than a year, Sean said the approach has delivered some incredible results.

RELATED: Thinking outside the (agriculture) box to drive ag innovation

“AMPC’s advanced manufacturing program is now valued at $24.8 million worth of projects and project concepts, spanning 99 projects with 56 R&D providers, with 36 of those providers new to AMPC, and more excitingly, mostly new to the meat processing sector,” he explained.

Related organisations

-contain-250x120.jpg)

-crop-672x478.png)

Military precision required

While DARPA deals with military technology, the latest industry challenge being thrown down by AMPC requires military precision.

“We’re putting the call out to see if there’s technology available that could make waterless knife sterilisation for meat processing plants a reality,” said Sean.

“Currently, operators in abattoirs worldwide must clean their tools between carcasses and this means dipping the tool – a knife – into a steriliser pot of hot water for a minimum of six seconds, which means two knives are needed at each station so the operator can keep moving to the next carcase.”

While industry has supported several R&D-led investigations into waterless applications in the red meat sector in the past, the vast majority didn’t focus specifically on knife and tool sterilisation – and that’s the key focus on the new AMPC challenge.

“When you look at the energy and water usage in our industry, a high proportion goes towards knife or equipment sterilisation.”

Essentially this is a really methodical approach to reducing our biggest use points but it’s also addressing global issues around water and energy use, too. If we could make this particular process waterless – or at least heavily reduced – that would be a massive win for industry and the greater global good.

-crop-672x478.png)

Solutions focus open to all sectors

In line with the AMPC Innovation Challenge platform to date, AMPC is specifically calling out to inventors and thought leaders who are new to the red meat sector.

“Potentially this is right up the alley of someone in the medical sector, or someone who works specifically in tech-solutions for desert locations where water is scarce.”

“Even if you know nothing about red meat or meat processing, we still want to talk with you if your technology has applications that could be made available to us.”

“We’re confident that the solution is out there but just not in our sector and not the service providers we ordinarily work with. If we keep asking the same people to look at the same problems we’ve had for the past 50 years, we’re simply not going to advance.”

“The ultimate breakthrough would be a knife that you never have to clean that still adheres to Australia’s red meat processing audited HACCP (Hazard Analysis Critical Control Point) standards.

Sean said AMPC is also open to consortia tenders.

“The more brains we’ve got on one problem from different skillsets is the goal here, as we’re actively searching for intellect from different backgrounds to increase the numbers of potential approaches.”

This waterless sterilisation challenge is underpinned by a five-stage plan that AMPC hope to complete with an adoption phase during 2024.

“We spent the first part of 2021 looking at previous developments and existing solutions to ensure we weren’t trying to reinvent the wheel – or even part of it – and make sure that what we are looking for is necessary.”

“For the remainder of 2021 and throughout 2022 we’ll be holding provider workshops for those who are ready to rethink the existing approaches to knife and tool sterilisation.”

RELATED: Waterless lamb frenching reducing 210,000 knifing path actions per shift to zero

“The key here is obviously eliminating or reducing water and energy use, followed by reducing the time to sterilise the tools, eliminate cost and effort of audits, all while ensuring that food safety and operating licences are not compromised at all.

“2023 to 2024 will focus on building and evaluating prototypes, deploying, and refining the most promising concepts, and look at leveraging the learnings from the previous stages to see if there are other uses for the applications.

“We’re confident that by 2024 we’ll be supporting early adopters of the technology we uncover"

If you are a problem solver or innovator who believes they can help the red meat industry, learn more and enquire here.

-crop-850x675.png)

Looking for engagement?

Showcase your commercialisation opportunity today.

Talk to our team to discuss how growAG. can connect your innovation to industry.

Have questions? Find answers to our most frequently asked questions on research projects, commercial opportunities, organisations and more.