-contain-250x120.jpg)

Waterless lamb frenching: reducing 210,000 knifing path actions per shift to zero

Consumers love a classic rack of lamb, especially one that has been beautifully frenched. But lamb frenching in abattoirs is posing a significant WHS risk for abattoir staff. This repetitive action can multiply to over 210,000 knife actions per minute, per operational shift within a plant operating at 10 carcases per minute. The Australian Meat Processor Corporation is calling for solution providers with ideas for sustainable and safe alternatives to traditional frenching with knives or water.

res-crop-1185x680.png)

This story was originally published by Sean Starling on LinkedIn.

The Frenched lamb racks depicted in the lead image have probably been produced with operational staff undertaking repetitive knife cutting actions as depicted below.

With each 8-rib rack requiring at least 21 knife actions (and up to 23), this activity results in up to 210,000 knife actions per operational staff within a plant operating at 10 carcases per minute.

This task has both a WHS repetitive strain and knife laceration safety concern. Frenching is also the final point of product presentation handling (and inspection) prior to a consumer purchasing the product.

Related organisations

-contain-250x120.jpg)

Frenching a rack of lamb

Current Approaches

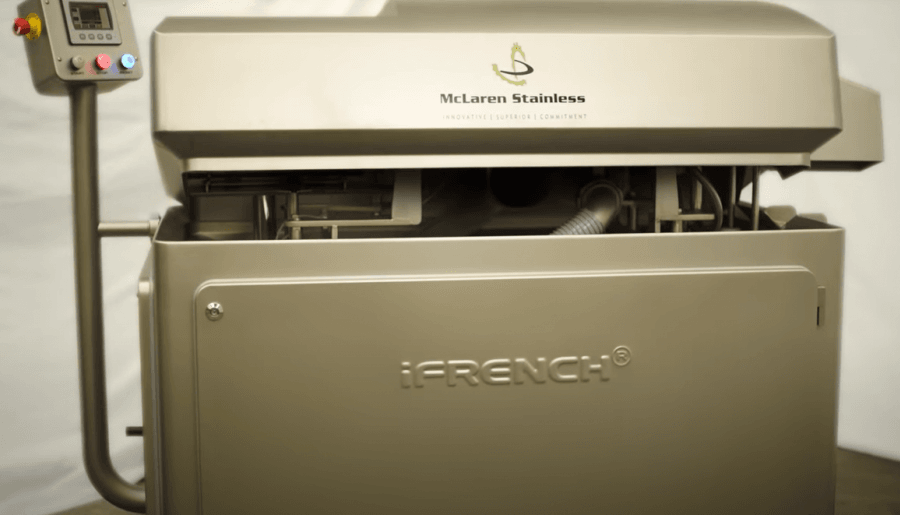

In Australia, most processing facilities rely on operational staff with knives to undertake this activity. There are instances in Australian plants using the McLaren Stainless water frenching solution. Although this solution works well it is not suitable for all Australian locations due to the water usage, water source, and resulting trade waste additional load with the product (intercostals) and water being discharged to drain.

The McLaren iFrench unit is a commercially viable unit for frenching. It is simple to use and compact, however, some Australian processors (39%) would prefer to use a waterless solution for the reasons alluded to above.

An industry report on the implementation of the iFrench can be located at this Link.

RELATED ARTICLES: Thinking outside the (agriculture) box to drive ag innovation

Mclaren Stainless iFrench

Past R&D

The industry has supported a number of investigations into waterless frenching including using wire cutting, ice jet cutting and robotic knives. These have all had a level of success but none to date have resulted in a commercial product offering.

- Wire cutting (Report Link)

- Ice Jet Cutting (Report Link)

- Using needles to determine where the intercostals/ribs locations are (Report Link)

AMPC Innovation Challenge

AMPC would like to hear from providers/developers who believe that they could develop a solution that:

- Remove operational staff form knifing (and holding) the product. Of the two removing the knife actions is the main foci (and hence semi-automated solutions are also an acceptable consideration).

- Uses no water (during operations).

- Recovers the intercostal as a saleable product item. Ideally can remove the intercostals as a single 'finger' of meat

If you are a solution provider or developer and would like to be financially supported by the Australian Meat Processor Corporation (AMPC) to demonstrate and evolve your offering in 'waterless frenching' and demonstrate it in meat processing environments please make an enquiry here.

-crop-850x675.png)

Looking for engagement?

Showcase your commercialisation opportunity today.

Talk to our team to discuss how growAG. can connect your innovation to industry.

Have questions? Find answers to our most frequently asked questions on research projects, commercial opportunities, organisations and more.