Aussie agritech startups Nitronic and MaxSil seek investment to scale impact

Two eco-friendly fertiliser solutions, Nitronic and MaxSil, both designed to boost productivity in the paddock, and reduce environmental impact, are seeking investment and commercial partners to scale production.

- Share via Facebook: Aussie agritech startups Nitronic and MaxSil seek investment to scale impact

- Share via LinkedIn: Aussie agritech startups Nitronic and MaxSil seek investment to scale impact

- Share via Twitter: Aussie agritech startups Nitronic and MaxSil seek investment to scale impact

- Share via E-mail: Aussie agritech startups Nitronic and MaxSil seek investment to scale impact

Australia's startup ecosystem is abuzz since evokeAG. 2024 with ground-breaking technologies on show at evokeAG. Startup Alley promising not only environmental sustainability but lucrative commercial opportunities for investors and industry partners.

Two novel fertiliser technologies, Nitronic and MaxSil, both of which caught the attention of investors and farmers at evokeAG. 2024 in Perth, are now seeking industry partners and investment to supercharge their impact.

Queensland-based startup, MaxSil produces a patented silicon fertiliser, using waste soda lime glass, by diverting unwanted coloured glass fines from landfill, and converting it into a granular and powdered form for farmers, with future plans for liquid application.

The end-product – containing more than 24 times more plant-available silicon (PAS) content than its competitors, and at one tenth of the cost – is designed for various agricultural crops to boost plant health, growth and yield, with increases of up to 15-30%.

The novel fertiliser currently produced at MaxSil’s Brendale pilot plant near Brisbane, offers a sustainable, low-cost and low-input solution for farmers to reduce fertiliser and pesticide application, with specific value for highly saline and acidic soils.

“The world has a significant problem with both saline and acid soils, some three million hectares in Australia, and 750m ha worldwide, where growth is not as good as it could be, and yields are down,” said MaxSil Managing Director, David Archer.

“We've come up with a cost-effective way of coping with salt and acidity in the soil, using MaxSil’s product, where every $1 invested yields an equivalent return of $2-$5.”

Successful fertiliser trials set to benefit Australian farms

MaxSil’s silicon fertiliser has shown strong yield results across a variety of cropping trials in Australia, Columbia, South East Asia, and South Africa where David sees prospects of a distribution partner for African markets.

For now, MaxSil is honing its focus on Australia’s broadacre cereals (wheat, barley, rice), sugar cane, tree crops, and horticulture segments. “We want to get the domestic market sorted and get some runs on the board.”

“We’ve proven that the product works to improve yield across a range of crops with successful farm and formal replicated trials in Western Australia, Queensland and New South Wales – verified by both farm trials and external providers – and now work supported by the University of Queensland.”

With a significant waste glass problem, and no current solution for processing, WA is MaxSil’s prized market, David explained. “There’s two million hectares of salt affected soils in WA’s wheatbelt, and one million hectares with acidity problems.”

Investment partners needed to scale business

After a decade of research and development, and proven financial returns, MaxSil is now seeking a $2m cornerstone investment to scale its market presence, backed by market interest from agricultural services providers Nutrien Ag Solutions and EE Muir & Sons, and major Australian waste companies.

“We’re seeking partners with experience in agriculture, global manufacturing and distribution of inputs, and marketing.”

- Learn more about MaxSil’s cornerstone investment opportunity, via AgriFutures growAG. here.

The investment will primarily support MaxSil’s marketing, management, and retail expansion in Australia, including additional staff, such as a sales agronomist and two managers for Far North QLD and WA, while also preparing for an IPO in the next two to three years.

The investment partners will be key in mapping out development and planning of MaxSil’s primary production plant (40,000t capacity) in Perth, WA, David explained, to service the state, and one day international markets – estimated to cost $12m.

“We’re already raising capital, between $500K-$1m, with our investors and shareholders, to optimise pilot plant performance.” Therefore, only a portion of the cornerstone investment will be used to upgrade the pilot plant facility, which launched in May 2023 after a $2.7m funding raise in December 2021, increasing its capacity from 8,000 tonnes to 12,000t.

David concluded, “I love the concept of taking waste material and diverting it from landfill to increase crop yields in a time when they’re declining. To see that in practice is fantastic – it’s why I get out of bed each day, to help build more climate-resilient food systems.”

Nitronic: zero-emission nitrogen fertiliser to feed humanity

MaxSil’s purpose is echoed in Nitronic’s mission to tackle the urgent challenge of nitrogen fertilisers, which feed half the world, but contribute 3% of global greenhouse gas emissions.

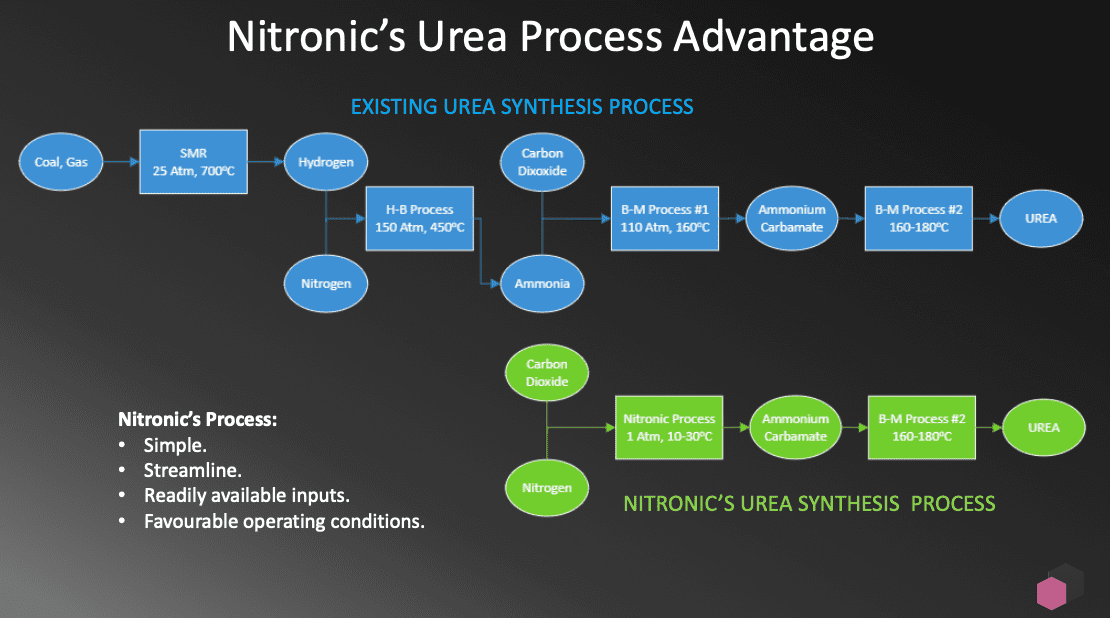

The Fremantle, WA based startup has developed a zero-emissions modular fertiliser manufacturing unit, using renewable energy and non-thermal plasma, which bypasses the conventional ‘Haber-Bosch’ fossil fuel (coal or gas) dependent process, required to produce ammonia.

- Learn more about Nitronic’s investment opportunity here, via AgriFutures growAG.

With 90% of Australia’s fertilisers imported, farmers face price volatility, transport costs, and supply uncertainties, often led by global conflict, currency fluctuations and shipping problems.

“Fertiliser prices fluctuate with gas prices and can triple in price, and we wanted to create something that wouldn’t fluctuate,” explained Nitronic CEO and Co-Founder, Dr Stuart Gunzburg, who co-founded the technology with Professor R. Mohan Sankaran, based at the University of Illinois.

“Fertilisers are the largest single cost input into their crops – it’s what can turn a good year into a bad year very easily. If we can produce fertilisers at a stable price in Australia, it takes a lot of worry away for farmers.”

Nitronic’s technology will empower farmers and generate regional employment opportunities, with a locally-produced nitrogen alternative, which “delinks the cost of fertiliser from gas commodity prices,” Stuart explained.

The two-step process eliminates the need for energy-intensive (high-temperature and high-pressure) processes, making it more cost-effective, simple and scalable. Unlike traditional methods, Nitronic combines carbon dioxide with nitrogen at room temperature and pressure to produce ammonium carbonate – the precursor to urea – using non-thermal plasma in small, affordable units.

Bright opportunity to commercialise modular fertiliser production

Nitronic is now seeking $1m pre-seed investment from strategic partners with connections in the fertiliser and chemical manufacturing space, and engineering experts to support the commercialisation of its novel fertiliser solution (TL-4), currently in its lab proof of concept stage.

- Learn more about Nitronic’s investment opportunity here, via AgriFutures growAG.

“We've proven the technology’s capability to produce the fertilisers we’re interested in.

Our next step will be determining the most efficient production process,” said Stuart.

Nitronic will not manufacture its systems overseas; instead, licence the technology. “We’ve lodged a patent application, and entered into a licensing agreement [with the University of Illinois] for the exclusive use of 50% of the technology.”

“There’s a lot of research we can benefit from for optimising the nonthermal plasmas, and producing what we require. We've got a 12-to-18-month research plan that we’ll conduct here in Australia, as well as the University of Illinois [that own 50% of the technology]. This plan involves optimising and scaling up pilot plant design and engineering, and the development process for ammonium nitrate.”

The ammonium nitrate process bears ‘highly useful’ application for agriculture, and the mining industry to potentially substitute explosives.

Nitronic has already garnered interest from key venture capital investors, including Artesian Capital’s investment fund, Grain Innovate, and even been approached by Coca-Cola.

“We’re discussing the development of technology and licensing to Australian companies like Yara, OCP, and in early-stage discussions with global fertiliser producer, the Mosaic Company.

“First and foremost, we want to assist Australian farmers, and then export our technology to the rest of the world.”

"The greatest guardians of the environment are farmers. So, if we can provide a solution, they can use in their production that's zero emission, that’ll add to their guardianship of the environment.”

Learn more about these promising commercial opportunities: Maxsil, and Nitronic, via the AgriFutures growAG. platform.

Nitronic: Novel sustainable fertiliser technology – Pre-seed raise

-

Led by

Nitronic

-

Opportunity type

Seeking interest, Seeking investment, Seeking partners

-

Readiness

Early (TRL 1-4)Describes the challenge or opportunity being pursued and undertakes preliminary R&D to determine if the concept is feasible.

Related highlights

Explore all highlights-crop-850x675.png)

Looking for engagement?

Showcase your commercialisation opportunity today.

Talk to our team to discuss how growAG. can connect your innovation to industry.

Have questions? Find answers to our most frequently asked questions on research projects, commercial opportunities, organisations and more.

-crop-770x475.png)