Innovative Aussie supply-chain monitoring solution keeping fresh food better for longer

An Australian agritech startup is revolutionising the way we manage fresh food supply-chains. With real-time monitoring technology, Escavox, with the support of Meat & Livestock Australia, is cutting food waste, protecting premiums, and improving market access for Australian farmers.

-crop-1185x680.png)

$20 billon of food is wasted in Australia every year. Globally, that figure is closer to $1 trillion. But how can we improve supply-chain management if we don’t know what, or where the problems are?

Until now, there has been no simple or cheap way of collecting, analysing, or using real-time data on variables like temperature and time across an entire supply-chain. Australian agritech startup Escavox has developed an innovative monitoring technology that shines a light on where and when fresh food quality and value suffers – and hence how waste can be avoided.

Related organisations

Food waste is a huge avoidable problem. An Aussie agtech startup has a solution

$670 million of Australian red meat is lost to waste each year due to problems in the cold-chain. As the son of cattle producers, Escavox co-founder Darryl Lyons understood, “just how much work producers put into the cattle they produce. Our processing facilities are the best in the world – but what happens after it leaves the farm? We’re potentially losing value all through the supply-chain from producers to processors to exporters.”

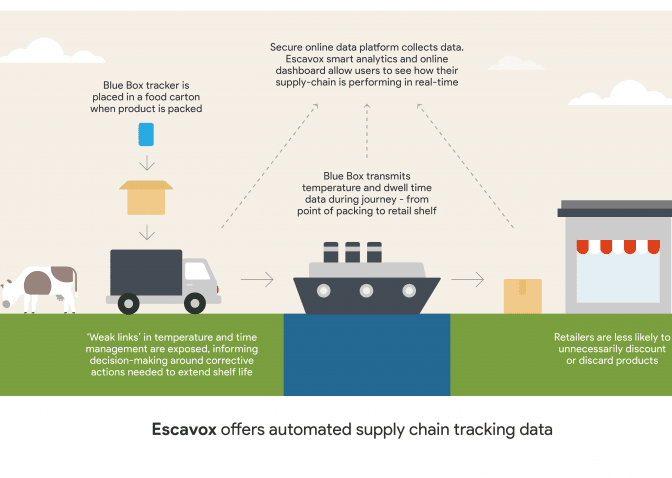

The Escavox solution is a ‘Blue Box tracker’. Described as CCTV for food, the tracker is placed in a fresh food carton at point of packing and travels through the supply-chain capturing data on dwell time, temperature and location. It can monitor all legs of a journey, from the processor to retail stores, providing real-time objective data to inform decision-making around corrective actions needed to extend shelf-life.

“What you can’t measure, you can’t manage,” explained Darryl. “We provide a lot of analytics and show trends over time to highlight where process changes might be required to improve the end result. For example, the processing plant might need to chill the product for longer so it can be loaded at a lower temperature, so that fluctuations in the next leg of the journey don’t impact it so much. There are lots of variables to influence and lots of opportunities to intervene.”

It’s technology which co-founder and CEO Luke Wood said gives the food a voice. “When you can see and understand what’s going on, your decision-making either becomes more informed, therefore superior, or you get to make decisions you wouldn’t have previously made.”

The Escavox 'blue box' tracker is always switched on, capturing and transmitting data in real-time as it moves through the supply chain. Each fully automated device operates independently, requiring zero human touch after it is deployed with the food. Customers who use the Escavox service can see their product's journey across the globe and the conditions to which their food is exposed. Even if the tracker is outside range, the data is conveyed once the tracker is back within cell-tower range.

A powerful partnership delivers remarkable value-add to red meat industry

Escavox has been working with Meat & Livestock Australia (MLA) to test a new approach to cold-chain monitoring and management aimed at maximising the shelf-life and brand reputation of Australian export red meat. By integrating the MLA shelf-life predictive model developed by the University of Tasmania, Escavox is giving red meat processors and exporters the full story of a product’s journey – when and where it went, what conditions it experienced, and how it will perform on the retail shelf and beyond to the consumer.

1,000 cartons of red meat were tracked from 20 exporters through unique supply-chain journeys – via sea and air freight – to 22 different countries. Each track was analysed for temperature, duration, shelf-life lost in the journey, shelf-life remaining on arrival (if held at the recommended temperature) and average shelf-life lost per day. Using these real-world examples, Escavox’s tech has for the first-time allowed exporters to identify crucial variability points within the cold-chain – from abattoir to arrival at the importing country.

Simone Tully, director of Australian Organic Meats, welcomed the end-to-end view of her product’s journey. “It is information that I am keen to share with all of our supply-chain partners so that we can collaborate further on what the data is telling us, and then make adjustments accordingly to our logistics planning to ensure we get the very best out of our product every time.”

The Escavox and MLA partnership has delivered some remarkable results. Australian officials were able to negotiate new food safety protocols for Middle East-bound red meat exports, extending from 70 to 90 shelf-life days for chilled lamb and 70 to 120 shelf-life days for chilled beef.

RELATED: On-farm benchmarking datasets help drive the value of agriculture

And sea freight was proved a realistic option for markets previously considered air freight-only – critical for exporters still reeling from the steep drop in air freight availability due to COVID-19 border closures. By supplying data to prove sea freight suitability for US shipments, export sales volumes lifted seven times, while freight costs were cut by $3.82/kg (relative to air freight).

This increased sales volumes and reduced freight costs. Fewer rejections and reduced insurance premiums. Brand protection and enhanced market access. The return on investment to the red meat industry from its partnership with Escavox is tremendous.

Highlights

Escavox and MLA webinar

Highlights from Ian Jenson (MLA) and Long Huynh (MLA) at a Escaovx and MLA webinar, on adding more life to red meat.

Enhancing quality, protecting premiums and reducing waste - one supply-chain at a time

Escavox’s focus to date has been on Australia, starting with horticulture in 2019, moving into the meat sector in 2020 and early seafood trials starting in 2021. Now they’ve set their sights on expansion into international export markets like southern Africa and South America.

RELATED: Mango auto-harvester set to speed up picking by 90%

Luke explained, “We over simplify and say the southern hemisphere feeds the north. And for us it’s the high-sensitivity, high-value lines. Think berries, think mushrooms, avocado, broccoli, beef, lamb, chilled products.”

A Series B capital raise is underway to help with their global expansion, as they lock in partners who are aligned with the Escavox mission and have the capability to help deliver on it.

“The value to us is the information – and how do we get it to the right person at the right time,” Luke explained. “

Escavox are looking for partners in the technology space, as well as those with expertise in fine-tuning and deploying the product. “We are absolutely built for a partnership. We are but one part of the larger story.”

It’s a little Blue Box with a very big future.

To get involved and invest in Escavox you can explore their current investment opportunity here. ^

Enjoyed this story? Sign up for our newsletter here and stay up to date with our latest stories, news and opportunities.

^This investment opportunity is only for professional and sophisticated investors as defined in the Corporations Act 2001 (Cth). The content of this opportunity is intended for use by persons having professional experience in matters relating to investments and must not be acted or relied upon by any other person including, without limitation, retail clients.

-crop-850x675.png)

Looking for engagement?

Showcase your commercialisation opportunity today.

Talk to our team to discuss how growAG. can connect your innovation to industry.

Have questions? Find answers to our most frequently asked questions on research projects, commercial opportunities, organisations and more.