MLA funded BladeStop: a safety success story

MLA funded BladeStop technology is now bringing huge safety benefits for workers in processing plants across 25 countries.

- BladeStop band saw safety system has reached a milestone of 1,000 units installed in processor plants across the world.

- Developed by Machinery Automation and Robotics (now a part of Scott Technology) with funding from the MLA Donor Company, the technology reduces the risk of serious injury for workers by mechanically stopping the blade when the unit senses that the operator has come into contact.

- BladeStop band saw safety system has reached a milestone of 1,000 units installed in processor plants across the world.

- Developed by Machinery Automation and Robotics (now a part of Scott Technology) with funding from the MLA Donor Company, the technology reduces the risk of serious injury for workers by mechanically stopping the blade when the unit senses that the operator has come into contact.

MLA funded BladeStop technology is now bringing huge safety benefits for workers in processing plants across 25 countries.

Scott Technology, the industry developer, recently announced the milestone of 1,000 BladeStop band saws installed worldwide.

Optimal safety

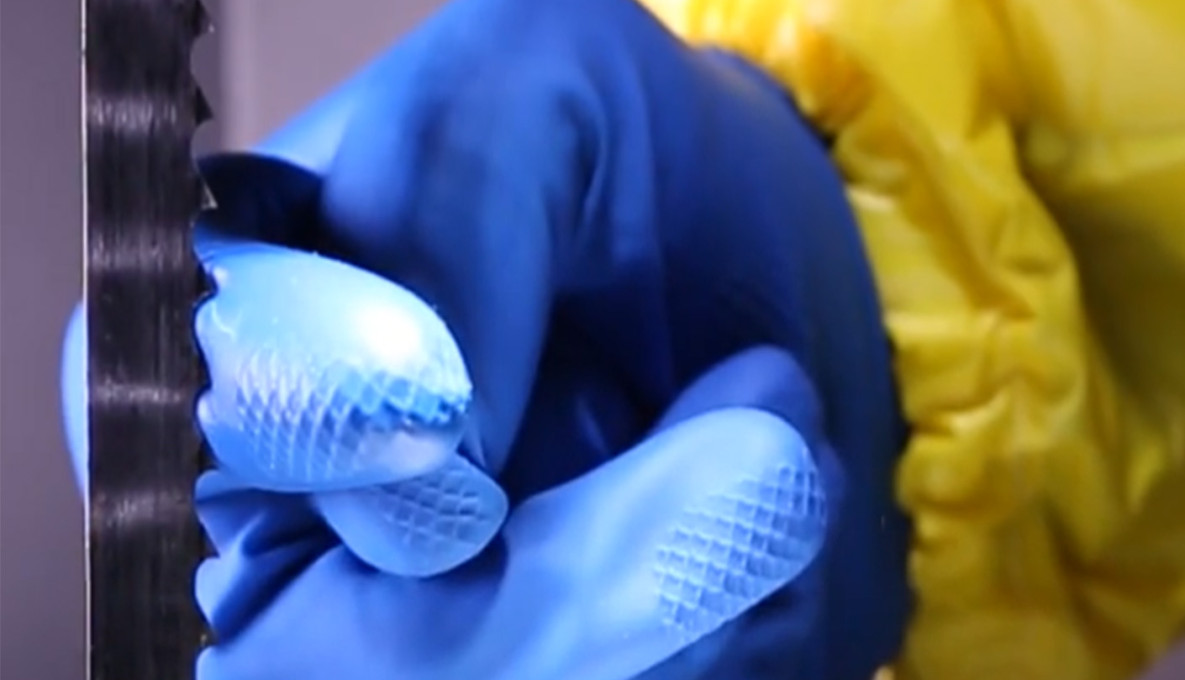

The challenge was to develop a mechanical braking mechanism for band saws, commonly used in meat processing, that is capable of stopping the blade when the unit senses that the operator has come in contact.

BladeStop bandsaw technology has done this successfully and is capable of stopping the blade within 15 milliseconds. This can mean the difference between a loss of limb injury for an operator, or just a skin cut.

Along with the touch sensing capability, BladeStop is also supplied with the GloveCheck™ sensing system which detects the operator’s gloves moving at high speeds in a zone directly upstream from the blade.

Complimenting the mechanics, the BladeStop Connect data recording system was developed to capture real time and historical data from an individual operator log in. This operational log provides detailed shift reporting and machine status.

Data from all connected saws are displayed in a web application and offer critical system information such as:

- overview of bandsaw status

- operator hours/access

- BladeStop and/or GloveCheck™ triggers

- bandsaw faults, warnings and other events

- saw utilization information

- saw run hours

- saw maintenance details

- operation and maintenance manuals.

Outcomes that make a difference

Our investment over five years to bring this technology to market has meant impactful outcomes in safety for workers in meat processing and industry benefits. It lessens the economic and social effects that result from serious workplace injuries and provides an even safer work environment to help attract and retain staff to the meat processing industry.

MLA Donor Company no longer fund the program as the technology is being widely adopted in the marketplace.

BladeStop is designed and manufactured in Australia.

For more information on BladeStop, please reach out to Chris Ruberg and Darryl Heidke.

Related organisations

-crop-850x675.png)

Looking for engagement?

Showcase your commercialisation opportunity today.

Talk to our team to discuss how growAG. can connect your innovation to industry.

Have questions? Find answers to our most frequently asked questions on research projects, commercial opportunities, organisations and more.